The advantages of Weinmann Haus

Independent of the weather

fast and dry technology

Minimum waste

low-waste technical solutions

Extremely fast

the building can be completed in days

Energy saving

low heat loss, more efficient energy use

Sustainable

we work exclusively with natural building materials

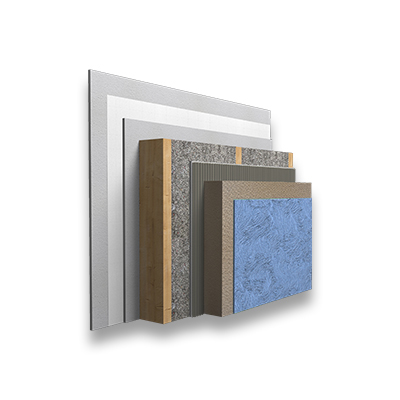

Premium building materials

high quality construction products

Waste management

Environmental consciousness is a very important concept in today’s developing world, and Weinmann Haus pays particular attention to it. We take great care in the manufacture of our custom-made building boards and vapour control films, so the amount of waste generated is kept to a minimum.

Thanks to our blown-in insulation, we can even produce walls without creating any waste at all. The adhesives we use have no release film, reducing the amount of waste generated.

As most of the materials used are naturally occurring materials, such as wood or gypsum, we can also recycle the waste we generate. We use natural, environmentally responsible materials that are predominantly recyclable, so the ecological footprint of our buildings is minimal.

Quality assurance

We currently have 13 people involved in the production process. With this number of employees, we are able to construct 80 buildings of 100 m2 per year, which means that we can construct our customers’ wall structures and roof elements from the materials used in 3 days. Our total annual capacity is 300 buildings.

The entire process of manufacturing and building Weinmann Haus is carried out by a professional and motivated team, who always carry out their tasks with the utmost attention and precision. We provide ongoing professional training for new and existing colleagues, and we invite our suppliers to participate in annual professional training courses.

The production process takes place under controlled factory conditions throughout, enabling us to produce high quality structures in our factory. Our independent quality control department is actively involved in checking that the items produced during manufacturing meet our expected and assured high quality standards and the expectations of our customers. The control process is already in place before production starts, for the raw materials that are supplied and used.

What are the advantages of prefabricated housing technology?

Whether it’s a prefabricated house built on site or a prefabricated large-panel prefabricated house, the vast majority of single-family housing projects in Western countries are built using prefabricated house technology. In the last few years, 40% of detached houses in Austria and 60% in Switzerland have been built using this technology. Not to mention America, where the figure is 90% – although American lightweight construction is far from being confused with prefabricated systems. The winds of this trend have been blowing in our direction in recent years. The reason for this is that in our country, too, there are more and more comparative analyses of lightweight and traditional (brick, ceramic, other small element) construction technologies.

In recent years, the number of builders in Hungary opting for prefabricated technology has increased more than fivefold. On a percentage basis, this represents around 15-20% of domestic house building.

Changing mindsets: environmental awarenessand reducing ecological footprint

As a responsible manufacturer, Weinmann Haus places a high priority on green development and is constantly reducing the use of building materials with high emissions. Properly constructed from materials with a low ecological footprint, the building will create a timeless and healthy home for its residents.

10% more useful floor area

In contrast to the wall thickness of a 30 cm thick prefabricated house, a brick wall with similar heat transfer parameters should be at least 45 cm thick. For a 100 m2 house, this could mean around 8 m2 and an average cost of HUF 5 million. Houses built with lightweight construction technology allow for more efficient use of space. For those with smaller plots, this can be a very important factor.

Cool in summer, warm in winter

Thanks to their improved thermal insulation, prefabricated houses with prefabricated technology outperform their conventional counterparts in terms of thermal performance.

Heating and cooling costs close to 0

Low heat loss, more sustainable, and therefore significantly lower cooling and heating costs for such houses. Heating and cooling costs are also typically 30-50 percent lower than in our standard houses.

Quick, orderly execution

Prefabricated houses built with large-panel technology arrive on site almost "ready to build", with no drying or standing times. If properly prepared and coordinated work is carried out, a finished house can be completed in as little as 3 months.

Accuracy, formality

The prefabricated wall, slab and roof panels are manufactured to a high degree of precision under factory conditions. The cutting machine starts the machining process by cutting the beams to size, which are always accurate to the millimetre.

Noise and vibration protection

In areas more frequently affected by earthquakes - such as. Japan - around 90% of family housing is also frame-framed, as it is much better able to resist horizontal movement. In the case of an earthquake, it is observed that there is less damage, fewer injuries and fewer deaths in such buildings.

Stability and mechanical resistance

Prefabricated houses are also designed by structural engineers and their load-bearing capacity is backed up by serious calculations. All of our houses are resistant to any kind of weather in our climate.

Make your ideas come true!

Ask for a personalised quote and personal consultation!