Roof structure with nail plates

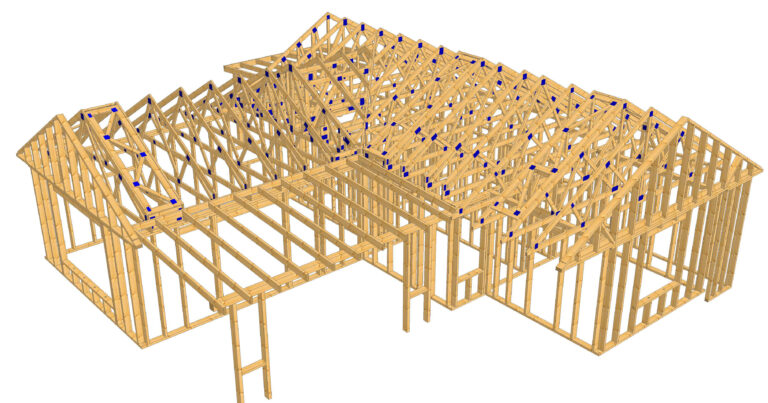

Truss roofs are advanced engineering structures suitable for the construction of roofs for single-family homes, condominiums and industrial facilities. It can be used for a wide range of applications from simple gable roofs to complex roof structures. We manufacture the nail plate holders under controlled factory conditions using special machinery.

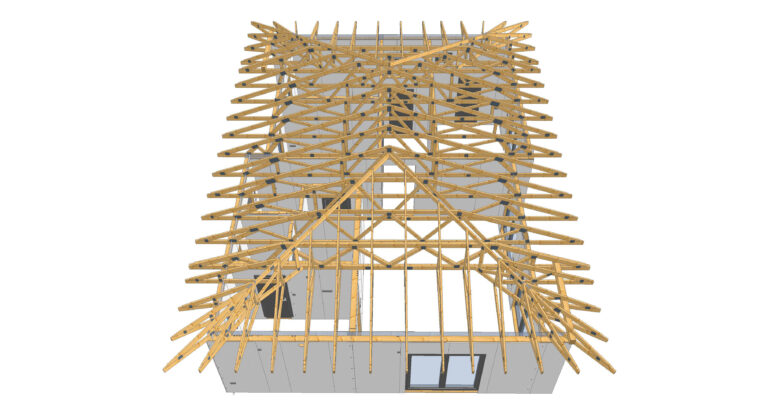

Roof design with segmental sheeting

For each building, a complete structural analysis is carried out for the building contour, surveyed or planned, with the geometry according to the architect’s plans, based on Eurocode. The detailed calculation aims to optimise the utilisation of the supporting structure and the use of materials. The structural calculations result in a production design, which includes the dimensions of all the wooden elements, the node configurations and the required fasteners. As part of the design, in addition to the production drawings, the construction design documentation for the assembly is prepared together with the material collections.

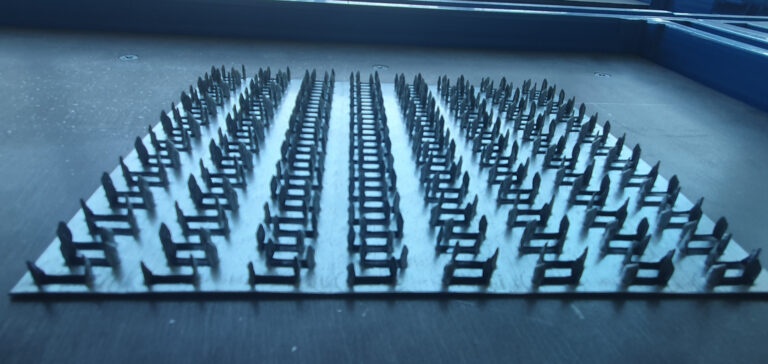

Sheet metal materials

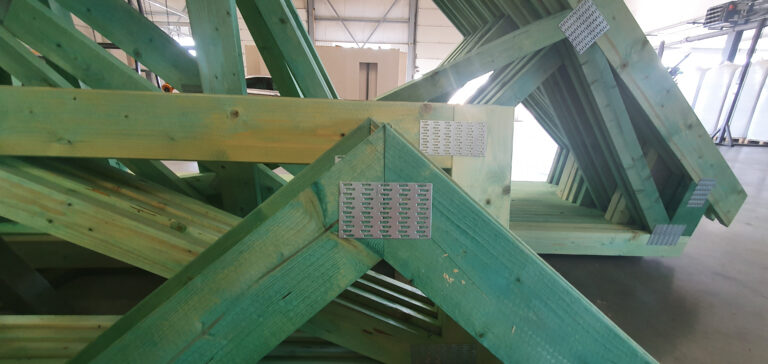

The brackets are made of CE certified KVH wood elements with 45×95 mm and 45×145 mm cross-sections, treated with insecticides and flame retardants. The wooden elements are connected at the node by pressed nail plates on both sides. The nail plates are thin steel plates, 1.5-2 mm thick, with punched nails bent out at 90°.

Roof structure with nail plates

manufacturing process

Production plans are created in a format that can be processed by the CNC machine. The cutting machine cuts the elements of different sizes from the fibre material by rotating them together and optimising the material, and performs the geometric shaping. After cutting, the wood must be treated with an insecticidal and fire retardant layer. After that, the support elements are sorted and the supports are assembled. The connection points will be fitted with the appropriate cross-sectional nailing plates. The boards are then pressed into the wood by machine. During assembly, we continuously check the geometric dimensions, and the final product is then stored and dispatched after final inspection.

The advantages of the Weinmann Haus roofing system

- quality-controlled, treated timber

- large spans can be bridged without internal load-bearing walls

- reliable and cost-optimised structural analysis for each roof structure

- prefabricated and quality controlled structure under factory conditions

- high dimensional accuracy

- quick assembly, with the help of a crane the complete support structure can be installed in a few hours

- material savings, thus a lower ecological footprint than traditional structures

- the roof structure is also the end slab, no need for a separate slab structure

- can be fitted with any type of shell or solar panel systems

- loading space can be created in the attic

- can be used for any lightweight construction or conventional technology

- scheduled production capacity, on-time production

- precise crane and installation instructions

- manufacturer’s guarantee for the support structure

Make your ideas come true!

Ask for a personalised quote and personal consultation!